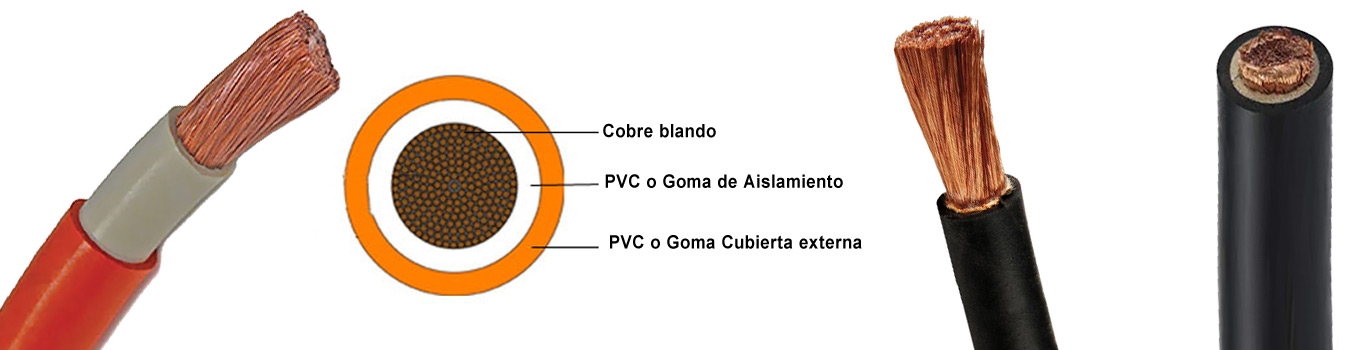

Construction:

- Bare copper conductor, according to HAR

- Up to 95 mm², the conductor corresponds approximately to Class 6, and from 120 mm², approximately to Class 5, according to VDE 0295

- Paper or synthetic tape separator

- Outer sheath: EM rubber compound

- Area of use

- Use the welding cable only under compliance with EN 50565-2

- For use with hand electrodes up to 100 V

- Suitable for use in dry or wet areas.

- For transmitting high currents from the electrical device to the welding tool

- Product characteristics

- Flame-retardant, according to IEC 60332-1-2

Applications:

These cables are used as a connection between the welding generator, the hand-held electrode, and the workpiece. They are suitable for use in the automotive industry, shipbuilding, transport and conveyor systems, toolmaking machinery, welding robots, etc.

These cables retain their high flexibility even under the influence of ozone, light, oxygen, shielding gases, oil, and gasoline. The robust construction of these cables makes them resistant to high and low temperatures, fire, ozone and radiation, oils, acids, greases, and gasoline.

These cables are also ideal for outdoor installation in dry, humid, and wet areas.

Specification

Parameters of H01N2-D Cable Welding

| AWG | NO. OF CORES X NOMINAL CROSS-SECTIONAL AREA | NOMINAL INSULATION THICKNESS | NOMINAL OVERALL DIAMETER | NOMINAL WEIGHT OF COPPER | NOMINAL WEIGHT |

| #XMM² | MM | MM | KG/KM | KG/KM | |

| 8(320/32) | 1x10 | 2 | 7.7-9.7 | 96 | 135 |

| 6(512/32) | 1x16 | 2 | 8.8-11.0 | 154 | 205 |

| 4(800/32) | 1x25 | 2 | 10.1-12.7 | 240 | 302 |

| 2(1120/32) | 1x35 | 2 | 11.4-14.2 | 336 | 420 |

| 1(1600/32) | 1x50 | 2.2 | 13.2-16.5 | 480 | 586 |

| 2/0(2240/32) | 1x70 | 2.4 | 15.3-19.2 | 672 | 798 |

| 3/0(3024/32) | 1x95 | 2.6 | 17.1-21.4 | 912 | 1015 |

| 4/0(614/24) | 1x120 | 2.8 | 19,2-24,0 | 1152 | 1310 |

| 300 MCM (765/24) | 1x150 | 3 | 21.2-26.4 | 1440 | 1620 |

| 350 MCM (944/24) | 1x185 | 3.2 | 23.1-28.9 | 1776 | 1916 |

| 500 MCM (1225/24) | 1x240 | 3.4 | 25,0-29,5 | 2304 | 2540 |

Trusted Manufacturer

Based on high-quality products, a good reputation, and excellent service, we sincerely hope to establish mutually beneficial cooperation with domestic and foreign merchants and create a bright future together.

Our Clients

We are professional cable manufacturers. Thanks to the excellent quality of our cables and continuous product innovation, we export them to over 130 countries worldwide and have received numerous praises from our customers.

Our Workshop

HuaDong Cable Group was established in 1999 and covers an area of 66,000 square meters, located in the Xiuwu Industrial Zone of Jiaozuo City, China. We have 20 advanced production lines and 25 testing machines, with an annual production capacity of over 15 million kilometers.

Why choose Huadong cable?

Our vision is to become an internationally renowned brand in the cable industry. Customer satisfaction, employee advancement, and corporate development are our service principles; high standards, globalization, and building an international brand are our business philosophy.

Sobre HuaDong

Henan Huadong Cable Co., Ltd. was founded in 1999 and is a national high-tech enterprise integrating scientific research, industry, and trade. Huadong Cable is deeply involved in the construction of the Belt and Road Initiative and exports to over 130 countries worldwide, including Europe, South America, North America, the Middle East, Africa, Asia, and Oceania.

Technology HuaDong

Huadong Cable focuses on technology research and development, employing 60 professionals with advanced professional degrees and holding over 100 patents and utility models. Huadong Cable employs a team of experienced technical engineers to ensure cable quality.

Main products

Our main products include marine cables, power cables, aerial cables, flame-resistant cables, low-smoke halogen-free cables, rubber cables, high-temperature cables, instrument and control cables, solar cables, and other products.

ISO, SGS, BV certification; technical patents and product certification

TEAMS AND CLIENTS

Export countries

Technical patents

Annual production

Employees