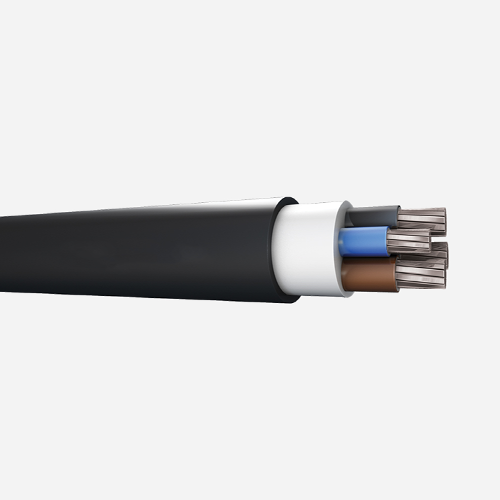

NAYY-J / NAYY-O

- Details:

- Cable structure

- Aluminum conductor,

- single-stranded according to DIN VDE 0295 cl. 1 / IEC 60228 cl. 1

- stranded according to DIN VDE 0295 cl. 2 / IEC 60228 cl. 2

- Conductor insulation: PVC, composite type DIV4 according to HD 603 S1

- Conductor identification according to DIN VDE 0293-308 / 0276-603

- Conductors stranded in concentric layers

- Common conductor sheath

- Outer sheath: PVC, composite type DMV5 according to HD 603 S1

- Sheath color: black

Technical data

- Power distribution cables according to DIN VDE 0276-603 / HD 603 S1 / IEC 60502

- Bending temperature range -5°C to +50°C

- Fixed installation -40°C to +70°C

- Permissible operating conductor temperature +70°C

- Permissible short-circuit temperature (maximum short-circuit duration 5 s) <= 300 mm² +160°C

- 300 mm² +140°C

- Nominal voltage U0/U 600/1000 V

- Test voltage 4000 V

- Maximum permissible voltage DC systems: Core/core 1.8 kV

- DC systems: Core/ground 0.9 kV

- AC systems: Single-phase systems, both outer conductors insulated 1.4 kV

- AC systems: Single-phase systems, both outer conductors insulated 1.4 kV Single-phase, one grounded outer conductor: 0.7 kV

- Three-phase systems: 1.2 kV

- Minimum bending radius for single-core systems: 15x outer diameter

- for multi-core systems: 12x outer diameter

- For heat load values, see “Technical Information”

Properties

The materials used during manufacturing do not contain cadmium, do not contain silicone and are free from substances harmful to the wetting properties of the lacquers.

Evidence

- Flame retardant according to HD 603 S1

- According to DIN VDE 0482-332-1-2 / DIN EN 60332-1-2 / IEC 60332-1-2

Notes

- re = round conductor, single-core

- rm = round conductor, multi-core

- se = sectional conductor, single-core

- sm = sectional conductor, multi-core

- The conductor is constructed metrically (mm²). The AWG designation is approximate and purely informative.

Application

Power cables for energy supply are installed outdoors, underground, in water, in concrete, indoors, in cable ducts, power plants, for industry and distribution boards, as well as in subscriber networks, where mechanical damage is not expected.

NAYRY Cable

- Construction:

- VOLTAGE: 0.6/1 kV

- CONDUCTOR: Class 2 round or sector-shaped aluminum

- INSULATION: PVC (polyvinyl chloride)

- SHIELDING: SWA (steel wire armor)

- SEPARATOR: Plastic tape or filler material

- OUTER SHEATH: PVC (polyvinyl chloride) – UV resistant

Application

The NAYRY-J/O is primarily used for power distribution in power plants, industrial facilities, and switchboards, as well as in local networks. It is suitable for fixed installations underground, indoors, in cable ducts, outdoors, and in water, where high protection against mechanical damage is required.

NYY-J/NYY-O Cable

- Construction:

- Nominal voltage Uo/U: 0.6/1 kV

- Conductor: RE: Class 1 solid copper conductor

- RM: Class 2 stranded copper conductor

- Insulation: PVC (polyvinyl chloride)

- Filling: PVC (polyvinyl chloride)

- Sheath: PVC (polyvinyl chloride)

- Temperature resistance: Fixed: -15°C to +70°C

- Flexed: -5°C to +50°C

- Minimum bending radius: Fixed: 12 x overall diameter

Application

Power and control cable for fixed installation. Can be used indoors, outdoors, underground, in concrete, and in water.

Specification

NAYY

| Número de núcleos x seg. transversal mm²" | conductor redondo/seccional | Ø exterior aprox. mm | Peso del aluminio kg/km | Peso aprox. kg/km | AWG |

| 4 x 16 | re | 23,0 | 186,0 | 750,0 | 6 |

| 4 x 25 | re | 26,0 | 290,0 | 950,0 | 4 |

| 4 x 35 | re | 28,5 | 406,0 | 1120,0 | 2 |

| 4 x 50 | se | 30,0 | 580,0 | 1151,0 | 1 |

| 4 x 70 | se | 35,0 | 812,0 | 1549,0 | 2/0 |

| 4 x 95 | se | 39,5 | 1102,0 | 2030,0 | 3/0 |

| 4 x 95 | sm | 39,5 | 1102,0 | 2030,0 | 3/0 |

| 4 x 120 | se | 44,0 | 1392,0 | 2400,0 | 4/0 |

| 4 x 120 | sm | 44,0 | 1392,0 | 2400,0 | 4/0 |

| 4 x 150 | se | 46,0 | 1740,0 | 3030,0 | 300 kcmil |

| 4 x 150 | sm | 46,0 | 1740,0 | 3030,0 | 300 kcmil |

| 4 x 185 | se | 51,0 | 2146,0 | 3650,0 | 350 kcmil |

| 4 x 185 | sm | 51,0 | 2146,0 | 3650,0 | 350 kcmil |

| 4 x 240 | se | 56,0 | 2784,0 | 4800,0 | 500 kcmil |

| 4 x 240 | sm | 56,0 | 2784,0 | 4800,0 | 500 kcmil |

| 4 x 300 | se | 64,0 | 3480,0 | 5596,0 | 600 kcmil |

| 4 x 300 | sm | 64,0 | 3480,0 | 5596,0 | 600 kcmil |

| 5 x 10 | re | 22,0 | 145,0 | 637,0 | 8 |

| 5 x 16 | re | 25,0 | 232,0 | 832,0 | 6 |

| 5 x 25 | re | 28,0 | 363,0 | 1175,0 | 4 |

| 5 x 35 | re | 31,0 | 508,0 | 1399,0 | 2 |

| 5 x 50 | rm | 35,0 | 725,0 | 1855,0 | 1 |

| 5 x 70 | rm | 40,0 | 1015,0 | 2351,0 | 2/0 |

| 5 x 95 | rm | 45,0 | 1378,0 | 3071,0 | 3/0 |

| 5 x 120 | rm | 49,0 | 1740,0 | 3631,0 | 4/0 |

| 5 x 150 | rm | 57,8 | 2175,0 | 4405,0 | 300 kcmil |

| 5 x 185 | rm | 61,5 | 2683,0 | 5420,0 | 350 kcmil |

| 5 x 240 | rm | 70,0 | 3480,0 | 6860,0 | 500 kcmil |

| 1 x 35 | re | 13,0 | 102,0 | 240,0 | 2 |

| 1 x 50 | re | 15,0 | 145,0 | 360,0 | 1 |

| 1 x 70 | rm | 16,5 | 203,0 | 410,0 | 2/0 |

| 1 x 95 | rm | 19,0 | 276,0 | 570,0 | 3/0 |

| 1 x 120 | rm | 20,5 | 348,0 | 691,0 | 4/0 |

| 1 x 150 | rm | 22,5 | 435,0 | 804,0 | 300 kcmil |

| 1 x 185 | rm | 25,0 | 537,0 | 979,0 | 350 kcmil |

| 1 x 240 | rm | 28,0 | 696,0 | 1253,0 | 500 kcmil |

| 1 x 300 | rm | 30,0 | 870,0 | 1395,0 | 600 kcmil |

| 1 x 400 | rm | 34,0 | 1160,0 | 1890,0 | 750 kcmil |

| 1 x 500 | rm | 38,0 | 1450,0 | 2600,0 | 1000 kcmil |

| 1 x 630 | rm | 43,0 | 1827,0 | 2780,0 | 1250 kcmil |

NAYRY

| NÚMERO DE NÚCLEOS x seg. transversal mm²" | ÁREA DE LA SECCIÓN TRANSVERSAL NOMINAL mm² | TIPO DE CONDUCTOR | DIÁMETRO TOTAL NOMINAL mm | PESO NOMINAL kg/km |

| 3+1 | 35+16 | SM/RM | 31 | 1460 |

| 3+1 | 50+25 | SM/RM | 35.7 | 1910 |

| 3+1 | 70+35 | SM/RM | 39.6 | 2460 |

| 3+1 | 95+50 | SM/RM | 46 | 3035 |

| 3+1 | 120+70 | SM/RM | 49 | 3785 |

| 3+1 | 150+95 | SM/RM | 54.5 | 4610 |

| 3+1 | 185+95 | SM/RM | 59.8 | 5425 |

| 3+1 | 240+120 | SM/RM | 68.9 | 6575 |

| CARACTERISTICAS ELECTRICAS | ||||

| ÁREA DE LA SECCIÓN TRANSVERSAL NOMINAL mm² | CAPACIDAD DE TRANSPORTE DE CORRIENTE | RESISTENCIA MÁXIMA DEL CONDUCTOR A 20°C | ||

| IN AIR | IN GROUND | |||

| 35+16 | 101 | 123 | 0.868/1.910 | |

| 50+25 | 121 | 145 | 0.641/1.200 | |

| 70+35 | 155 | 180 | 0.443/0.868 | |

| 95+50 | 189 | 216 | 0.320/0.641 | |

| 120+70 | 220 | 246 | 0.253/0.443 | |

| 150+95 | 249 | 276 | 0.206/0.320 | |

| 185+95 | 287 | 313 | 0.164/0.320 | |

| 240+120 | 339 | 362 | 0.125/0.253 | |

NYY

| Número de núcleos y sección transversal nominal | Figura de cobre | Diámetro total | Peso aproximado. | Capacidad de transporte de corriente de tierra | Capacidad de transporte de corriente de aire |

| 1 x 25 RM | 240,0 | 12 | 370 | 138 | 114 |

| 1 x 35 RM | 336,0 | 14 | 480 | 164 | 139 |

| 1 x 50 RM | 480,0 | 16 | 640 | 195 | 169 |

| 1 x 70 RM | 672,0 | 17 | 850 | 238 | 213 |

| 1 x 95 RM | 912,0 | 19 | 1.12 | 286 | 264 |

| 1 x 120 RM | 1.152,0 | 21 | 1.375 | 325 | 307 |

| 1 x 150 RM | 1.440,0 | 23 | 1.66 | 365 | 352 |

| 1 x 185 RM | 1.776,0 | 25 | 2.05 | 413 | 406 |

| 1 x 240 RM | 2.304,0 | 28 | 2.634 | 479 | 483 |

| 1 x 300 RM | 2.880,0 | 30 | 3.295 | 541 | 557 |

| 1 x 400 RM | 3.840,0 | 32 | 4.231 | 614 | 646 |

| 1 x 500 RM | 4.800,0 | 34 | 5.284 | 693 | 747 |

| 1 x 630 RM | 6.048,0 | 42 | 6.85 | 777 | 858 |

| 3 x 10 RE | 288,0 | 18 | 645 | 79 | 59 |

| 3 x 16 RE | 460,8 | 20 | 872 | 102 | 79 |

| 3 x 16 RM | 460,8 | 20 | 872 | 102 | 79 |

| 3 x 25 RM | 720,0 | 25 | 1.35 | 133 | 106 |

| 3 x 35 SM | 1.008,0 | 25 | 1.46 | 159 | 129 |

| 3 x 50 SM | 1.440,0 | 29 | 1.75 | 188 | 157 |

| 3 x 70 SM | 2.016,0 | 32 | 2.4 | 232 | 199 |

| 3 x 95 SM | 2.736,0 | 35 | 3.56 | 280 | 246 |

| 3 x 120 SM | 3.456,0 | 38 | 4.31 | 318 | 285 |

| 3 x 150 SM | 4.320,0 | 42 | 5.31 | 359 | 326 |

| 3 x 185 SM | 5.328,0 | 47 | 6.63 | 406 | 374 |

| 3 x 240 SM | 6.912,0 | 53 | 8.48 | 473 | 445 |

| 3 x 25/16 RM/RE | 873,6 | 25 | 1.513 | 133 | 106 |

| 3 x 35/16 SM/RE | 1.161,6 | 27 | 1.804 | 159 | 129 |

| 3 x 50/25 SM/RM | 1.680,0 | 31 | 2.349 | 188 | 157 |

| 3 x 70/ 35 SM | 2.352,0 | 35 | 3.117 | 232 | 199 |

| 3 x 95/ 50 SM | 3.216,0 | 39 | 4.167 | 280 | 246 |

| 3 x 120/ 70 SM | 4.128,0 | 44 | 5.19 | 318 | 285 |

| 3 x 150/ 70 SM | 4.992,0 | 47 | 6.161 | 359 | 326 |

| 3 x 185/ 95 SM | 6.240,0 | 53 | 7.673 | 406 | 374 |

| 3 x 240/120 SM | 8.064,0 | 59 | 9.85 | 473 | 445 |

| 3 x 300/150 SM | 10.080,0 | 65 | 11.9 | 535 | 511 |

| 4 x 25 RM | 960,0 | 27 | 1.632 | 133 | 106 |

| 4 x 35 SM | 1.344,0 | 27 | 1.959 | 159 | 129 |

| 4 x 50 SM | 1.920,0 | 32 | 2.595 | 188 | 157 |

| 4 x 70 SM | 2.688,0 | 36 | 3.488 | 232 | 199 |

| 4 x 95 SM | 3.648,0 | 41 | 4.637 | 280 | 246 |

| 4 x 120 SM | 4.608,0 | 43 | 5.689 | 318 | 285 |

| 4 x 150 SM | 5.760,0 | 49 | 6.973 | 359 | 326 |

| 4 x 185 SM | 7.104,0 | 54 | 8.663 | 406 | 374 |

| 4 x 240 SM | 9.216,0 | 60 | 11.14 | 473 | 445 |

| 5 x10 RE | 480,0 | 21 | 921 | ** | ** |

| 5 x10 RM | 480,0 | 21 | 921 | ** | ** |

| 5 x16 RE | 768,0 | 24 | 1.294 | ** | ** |

| 5 x16 RM | 768,0 | 24 | 1.294 | ** | ** |

| 5 x25 RM | 1.200,0 | 29 | 2.004 | ** | ** |

| 5 x35 RM | 1.680,0 | 30 | 2.575 | ** | ** |

| 5 x50 RM | 2.400,0 | 36 | 3.193 | ** | ** |

| 5 x70 RM | 3.360,0 | 40 | 4.722 | ** | ** |

| 5 x95 RM | 4.560,0 | 46 | 6.393 | ** | ** |

| 5 x120 RM | 5.760,0 | 50 | 7.095 | ** | ** |

| 5 x150 RM | 7.200,0 | 59 | 8.24 | ** | ** |

Trusted Manufacturer

Based on high-quality products, a good reputation, and excellent service, we sincerely hope to establish mutually beneficial cooperation with domestic and foreign merchants and create a bright future together.

Our Clients

We are professional cable manufacturers. Thanks to the excellent quality of our cables and continuous product innovation, we export them to over 130 countries worldwide and have received numerous praises from our customers.

Our Workshop

HuaDong Cable Group was established in 1999 and covers an area of 66,000 square meters, located in the Xiuwu Industrial Zone of Jiaozuo City, China. We have 20 advanced production lines and 25 testing machines, with an annual production capacity of over 15 million kilometers.

Why choose Huadong cable?

Our vision is to become an internationally renowned brand in the cable industry. Customer satisfaction, employee advancement, and corporate development are our service principles; high standards, globalization, and building an international brand are our business philosophy.

Sobre HuaDong

Henan Huadong Cable Co., Ltd. was founded in 1999 and is a national high-tech enterprise integrating scientific research, industry, and trade. Huadong Cable is deeply involved in the construction of the Belt and Road Initiative and exports to over 130 countries worldwide, including Europe, South America, North America, the Middle East, Africa, Asia, and Oceania.

Technology HuaDong

Huadong Cable focuses on technology research and development, employing 60 professionals with advanced professional degrees and holding over 100 patents and utility models. Huadong Cable employs a team of experienced technical engineers to ensure cable quality.

Main products

Our main products include marine cables, power cables, aerial cables, flame-resistant cables, low-smoke halogen-free cables, rubber cables, high-temperature cables, instrument and control cables, solar cables, and other products.

ISO, SGS, BV certification; technical patents and product certification

TEAMS AND CLIENTS

Export countries

Technical patents

Annual production

Employees