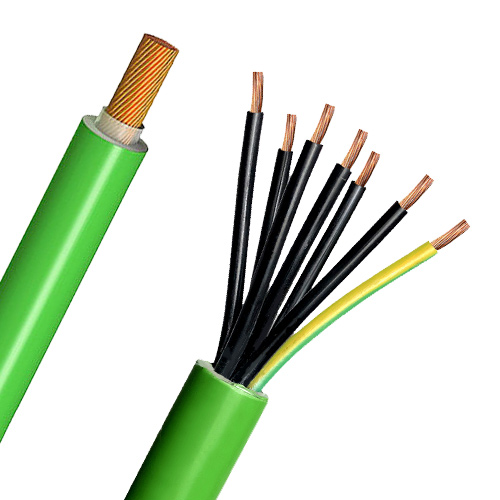

Construction:

- — Conductor: Flexible, annealed copper, class 5 (UNE-EN 60228 / IEC 60228).

- — Insulation: Cross-linked polyethylene (XLPE). XLPE (IEC 60502-1) and XLPE type DIX 3 (UNE-HD 603-1).

- — Sheath: Halogen-free thermoplastic polyolefin. Type ST 8 (IEC 60502-1) and type DMZ-E (UNE 21123-4).

- • Rated voltage (Uo/U): 0.6/1 kV AC.

- • Range: Single-conductor or multi-conductor. Formations: 1X(1.5-…-500) mm² / 2X(1.5-…-35) mm² / (3-4)X or G(1.5-…-120) mm² / 5G(1.5-…-95) mm².

- • Reaction to fire (CPR – EN 50575 & EN 13501-6): Class Cca-s1b,d1,a1.

- • Other fire performance (where the CPR Regulation does not apply): Flame retardant, fire retardant, halogen-free, and low gas and smoke emission, with low opacity/toxicity/corrosivity/conductivity (IEC 60332-1-2, IEC 60332-3-24, IEC 61034-2, IEC 60754-1 and IEC 60754-2).

Applications:

Suitable for indoor and outdoor installations, on open supports, in conduits, or buried underground. When laying cables on clamps, the horizontal distance between the clamps must not exceed 20 times the cable diameter. The distance also applies between support points when laying on other types of supports (e.g., on cable racks, trays, or ladders). Under no circumstances must this distance exceed 80 cm.

If single-core cables (1X) are installed separately, clamps made of plastic or non-magnetic metals must be used. Cables and cable bundles must be secured in such a way as to avoid damage in the form of penetrating marks due to thermal expansion. The cable must not be subjected to compressive stresses that could damage it.

- — Ambient operating temperature range:

- • Minimum: −30°C (fixed installation, static, protected, and not exposed to mechanical damage, shock, or vibration).

- • Maximum: +60°C.

- — Minimum laying temperature during installation and accessory assembly: 0°C. This temperature applies to the cables themselves, not to the environment. If the cables are at a lower temperature, they must be warmed up (e.g., by storing them for a reasonable period of time in a heated room or hall).

- — Minimum bending radius (final position): 4xD (D<25); 5xD(25≤D≤50); 6xD(D>50). D= cable outer diameter (mm).

- — Maximum tensile stress during installation:

- • F = 50xS (N). “S” = nominal conductor cross-section (mm²). Applied to copper conductors.

- • F = 5xD² (N). “D” = outer diameter (mm). Applied to the outer sheath.

Specification

1~2 Cores RZ1-K Cable Parameters

| Number of conductors and nominal section | Insulation thickness | External diameter | Weight | Electrical resistance max. at 20ºC in CC |

| mm² | mm | mm | kg/km | Ω/km |

| 1 X 1,5 | 0,7 | 6,0 | 50 | 13,3 |

| 1 X 2,5 | 0,7 | 6,4 | 59 | 7,98 |

| 1 X 4 | 0,7 | 6,7 | 72 | 4,95 |

| 1 X 6 | 0,7 | 7,6 | 102 | 3,30 |

| 1 X 10 | 0,7 | 8,7 | 146 | 1,91 |

| 1 X 16 | 0,7 | 9,7 | 205 | 1,21 |

| 1 X 25 | 0,9 | 11,2 | 292 | 0,780 |

| 1 X 35 | 0,9 | 12,3 | 287 | 0,554 |

| 1 X 50 | 1,0 | 14,1 | 530 | 0,386 |

| 1 X 70 | 1,1 | 15,9 | 720 | 0,272 |

| 1 X 95 | 1,1 | 18,0 | 954 | 0,206 |

| 1 X 120 | 1,2 | 19,7 | 1190 | 0,161 |

| 1 X 150 | 1,4 | 22,0 | 1474 | 0,129 |

| 1 X 185 | 1,6 | 24,3 | 1798 | 0,106 |

| 1 X 240 | 1,7 | 27,0 | 2330 | 0,0801 |

| 1 X 300 | 1,8 | 31,5 | 2900 | 0,0641 |

| 1 X 400 | 2,0 | 35,0 | 3650 | 0,0486 |

| 1 X 500 | 2,2 | 42,5 | 5010 | 0,0384 |

| 2 X 1,5 | 0,7 | 9,5 | 128 | 13,3 |

| 2 X 2,5 | 0,7 | 11,0 | 178 | 7,98 |

| 2 X 4 | 0,7 | 12,0 | 228 | 4,95 |

| 2 X 6 | 0,7 | 12,9 | 267 | 3,30 |

| 2 X 10 | 0,7 | 15,5 | 420 | 1,91 |

| 2 X 16 | 0,7 | 17,9 | 580 | 1,21 |

| 2 X 25 | 0,9 | 20,6 | 861 | 0,780 |

3~5 Cores RZ1-K Cables Parameters

| Number of conductors and nominal section | Insulation thickness | External diameter | Weight | Electrical resistance max. at 20ºC in CC |

| mm² | mm | mm | kg/km | Ω/km |

| 3 G 2,5 | 0,7 | 11,3 | 197 | 7,98 |

| 3 G 4 | 0,7 | 12,6 | 265 | 4,95 |

| 3 G 6 | 0,7 | 13,9 | 341 | 3,30 |

| 3 G 10 | 0,7 | 16,8 | 531 | 1,91 |

| 3 X 16 | 0,7 | 18,4 | 710 | 1,21 |

| 3 X 25 | 0,9 | 21,7 | 1018 | 0,780 |

| 3 X 35 | 0,9 | 23,8 | 1350 | 0,554 |

| 4 G 1,5 | 0,7 | 10,9 | 177 | 13,3 |

| 4 G 2,5 | 0,7 | 12,1 | 229 | 7,98 |

| 4 G 4 | 0,7 | 13,9 | 316 | 4,95 |

| 4 G 6 | 0,7 | 15,4 | 422 | 3,30 |

| 4 G 10 | 0,7 | 18,0 | 636 | 1,91 |

| 4 X 16 | 0,7 | 20,7 | 888 | 1,21 |

| 4 X 25 | 0,9 | 24,0 | 1275 | 0,780 |

| 4 X 35 | 0,9 | 27,5 | 1728 | 0,554 |

| 4 X 50 | 1,0 | 32,9 | 2418 | 0,386 |

| 4 X 70 | 1,1 | 38,1 | 3329 | 0,272 |

| 4 X 95 | 1,1 | 42,6 | 4344 | 0,206 |

| 4 X 120 | 1,2 | 51,7 | 6008 | 0,161 |

| 5 G 1,5 | 0,7 | 12,0 | 213 | 13,3 |

| 5 G 2,5 | 0,7 | 13,4 | 280 | 7,98 |

| 5 G 4 | 0,7 | 14,9 | 377 | 4,95 |

| 5 G 6 | 0,7 | 16,9 | 513 | 3,30 |

| 5 G 10 | 0,7 | 20,0 | 773 | 1,91 |

| 5 G 16 | 0,7 | 22,7 | 1098 | 1,21 |

| 5 G 25 | 0,9 | 27,0 | 1577 | 0,780 |

| 5 G 35 | 0,9 | 30,2 | 2111 | 0,554 |

| 5 G 50 | 1,0 | 35,8 | 2913 | 0,386 |

| 5 G 70 | 1,1 | 39,1 | 4576 | 0,272 |

| 5 G 95 | 1,1 | 44,2 | 5893 | 0,206 |

Trusted Manufacturer

Based on high-quality products, a good reputation, and excellent service, we sincerely hope to establish mutually beneficial cooperation with domestic and foreign merchants and create a bright future together.

Our Clients

We are professional cable manufacturers. Thanks to the excellent quality of our cables and continuous product innovation, we export them to over 130 countries worldwide and have received numerous praises from our customers.

Our Workshop

HuaDong Cable Group was established in 1999 and covers an area of 66,000 square meters, located in the Xiuwu Industrial Zone of Jiaozuo City, China. We have 20 advanced production lines and 25 testing machines, with an annual production capacity of over 15 million kilometers.

Why choose Huadong cable?

Our vision is to become an internationally renowned brand in the cable industry. Customer satisfaction, employee advancement, and corporate development are our service principles; high standards, globalization, and building an international brand are our business philosophy.

Sobre HuaDong

Henan Huadong Cable Co., Ltd. was founded in 1999 and is a national high-tech enterprise integrating scientific research, industry, and trade. Huadong Cable is deeply involved in the construction of the Belt and Road Initiative and exports to over 130 countries worldwide, including Europe, South America, North America, the Middle East, Africa, Asia, and Oceania.

Technology HuaDong

Huadong Cable focuses on technology research and development, employing 60 professionals with advanced professional degrees and holding over 100 patents and utility models. Huadong Cable employs a team of experienced technical engineers to ensure cable quality.

Main products

Our main products include marine cables, power cables, aerial cables, flame-resistant cables, low-smoke halogen-free cables, rubber cables, high-temperature cables, instrument and control cables, solar cables, and other products.

ISO, SGS, BV certification; technical patents and product certification

TEAMS AND CLIENTS

Export countries

Technical patents

Annual production

Employees